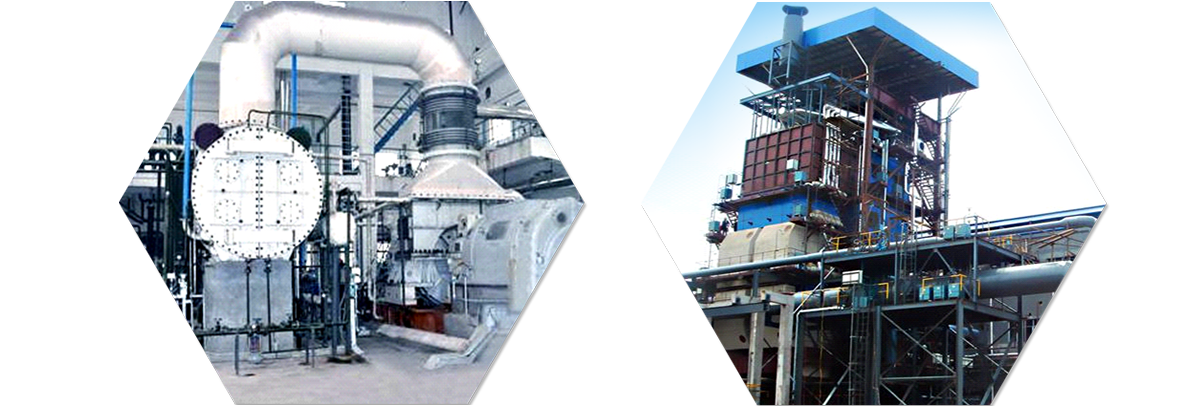

Guoshun Group has been engaged in large-scale heat exchange stations and large-scale thermal pipe network installation and renovation projects for many years. It is the earliest in Shandong area to engage in steel sleeve steel, plastic sleeve steel, thermal pipe network, power plant first station, steam-water heat exchange station, Water-water heat exchange station project enterprise.

Guoshun Group has the first-class qualification for general contracting of mechanical and electrical engineering construction. In order to serve users more comprehensively, it has realized a comprehensive service model integrating engineering installation and equipment production, and can engage in EPC, EP, and PC engineering services for various mechanical and electrical engineering. The business areas involve: electric power, chemical industry, papermaking, civil, metallurgy, building materials, environmental protection and many other industries. The construction area covers all provinces, cities and autonomous regions, and the construction capacity is at the forefront of the industry.

Guoshun Group is committed to the development and application of ground source heat pump and air source heat pump projects, and has constructed multiple ground source heat pump projects using underground pipe and water source technology.